Cold forging

A manufacturing process, which shapes a metal blank at ambient temperature. The process done by compression in closed dies delivers parts with less dimensional tolerances than parts forged hot, ensuring dimensional repeatability.

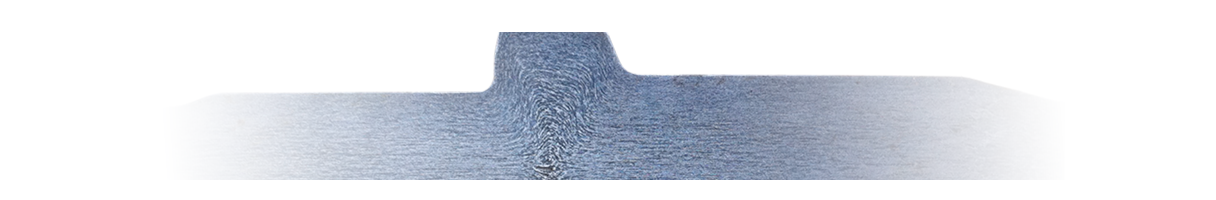

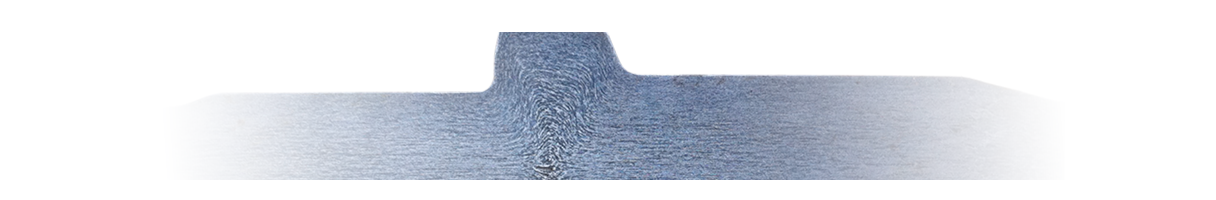

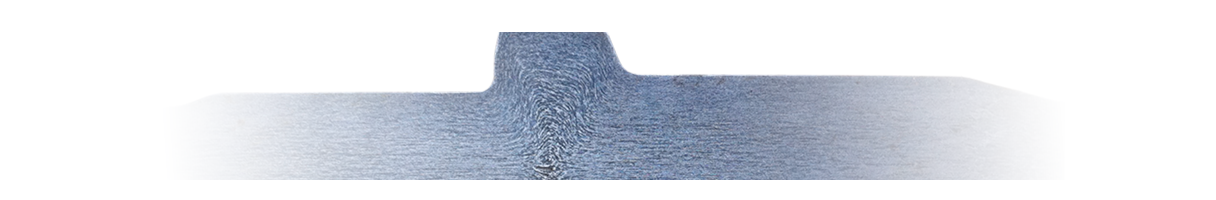

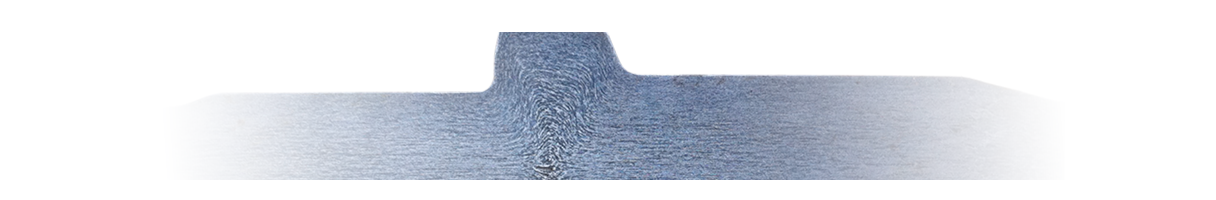

Fiber structure and temper

As the process permits the material to flow without removing or cutting the fibers along its extension, it guarantees exceptional improvements in the mechanical properties, increasing fatigue resistance.

Precision finishing

Cold forging ensures parts with close tolerances and excellent finishing, eliminating or reducing significantly machining operations.

Adjusting design

Metalcoop strives for the economic feasibility of a product by adjusting its project to the design of the finished, machined part and by choosing the best alternative in terms of process.